What is 21700 Battery Safety Vent?

Blog | Published by Alex on August 27, 2025

What is a 21700 Battery Safety Vent?

With the rapid development of electric vehicles, energy storage systems, and high-power electronic devices, 21700 battery have been widely used due to their high energy density, high-rate performance, and long cycle life. However, lithium-ion batteries may experience extreme conditions such as overcharging, short circuits, or thermal runaway during operation, leading to a rapid increase in internal pressure and the risk of explosion. Therefore, the safety vent (Safety Vent) has become a critical component in the design of 21700 lithium battery. The safety vent not only releases internal gas in emergency situations but also works together with other protective mechanisms to ensure the safety of the battery cell and the battery pack.

Definition and Working Principle of the 21700 Safety Vent

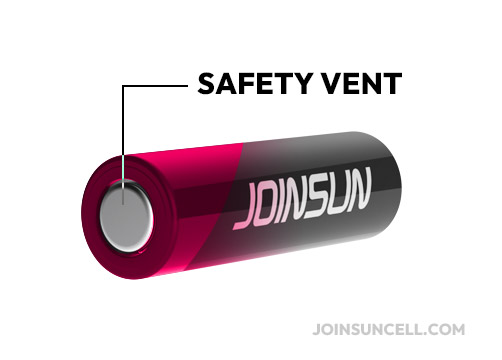

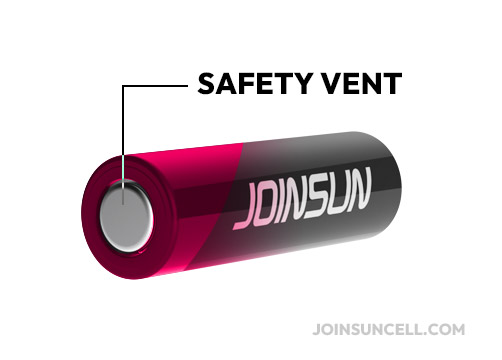

The safety vent is a safety device installed on the top cap of the 21700 battery. Its core function is to automatically open and release gas pressure when internal pressure exceeds a set threshold. A 21700 battery usually consists of a positive electrode, negative electrode, separator, electrolyte, and casing. Under normal conditions, internal pressure remains within a safe range. When excessive chemical reactions occur due to overcharging, external short circuits, or abnormal temperatures, large amounts of gas are generated inside the battery. The vent’s weak point or perforated metal piece breaks when the pressure reaches the set value, allowing the gas to escape in a controlled manner and preventing the battery casing from rupturing or exploding. For example,

21700 Battery of Joinsun.

Design Considerations of the 21700 Battery Safety Vent

(1) Vent Structure

The safety vent of a 21700 battery is typically designed as a cross, Y-shape, or ring-shaped perforation on the metal cap. The vent material is usually high-strength steel or aluminum alloy, ensuring it does not open accidentally during normal use but reliably operates under overpressure conditions.

(2) Pressure Setting

The vent’s activation pressure is determined by battery capacity, material characteristics, and operating environment. For 21700 batteries, the typical vent pressure range is 0.7 - 1.2 MPa, ensuring timely gas release under extreme conditions while avoiding frequent activation during normal operation.

(3) Vent Size and Gas Release Rate

The diameter and opening area directly affect the venting speed. If too slow, the top cap may bulge; if too fast, sparks or gas ejection may occur. Design requires fluid dynamics simulations and experimental validation for optimal sizing.

(4) Coordination with Other Safety Mechanisms

Safety vents often work together with Current Interrupt Devices (CID) and separator fuses. When internal pressure rises, the CID cuts off current, the separator fuse opens the local circuit, and the vent releases excess gas, achieving multiple layers of safety protection.

Role of the Safety Vent in Safety Management

(1) Thermal Runaway Protection

Thermal runaway in lithium batteries is often caused by overcharge, short circuit, or internal defects. The vent releases accumulated gas to slow down the temperature rise and reduce the risk of runaway propagation.

(2) Preventing Casing Rupture or Explosion

Cylindrical battery casings can deform or rupture under high pressure. The safety vent protects the casing by relieving internal pressure, maintaining structural integrity even under extreme conditions.

(3) Ensuring User and Device Safety

In electric vehicles, energy storage systems, or portable electronics, a single battery failure can trigger chain reactions. The vent effectively releases gas, reducing the likelihood of accidents and protecting users and devices.

Standards and Testing Methods for 21700 Safety Vents

To ensure reliability under various conditions, international standards define specific testing methods:

(1) IEC 62133

Specifies safety requirements for lithium batteries, requiring that the safety vent operates correctly under overcharge, short circuit, compression, impact, and penetration tests.

(2) UL 1642 and UL 2054

US standards require cylindrical lithium batteries to release gas effectively via the vent and prevent casing rupture under overpressure and thermal runaway conditions.

(3) Testing Methods

Pressure Test: Gradually increase internal pressure and verify vent activation threshold.

Temperature Rise Test: Cycle charge/discharge at high temperatures to check vent operation during early thermal runaway.

Aging Test: Assess vent reliability and consistency after multiple charge/discharge cycles.

Applications of the Safety Vent in 21700 Battery Lithium Cells

(1) Electric Vehicle Battery Packs

High-capacity 21700 battery are assembled into modules. The safety vent provides relief for individual batteries and works with cooling systems to prevent thermal runaway propagation.

(2) Energy Storage and UPS Systems

Hundreds to thousands of 21700 battery may be connected in parallel. Safety vents reduce system-level safety risks during overpressure or abnormal reactions.

(3) High-Power Portable Devices

Electric tools, drones, or e-bikes rely on the vent to safely release internal pressure during high-rate charging/discharging or unexpected short circuits.

Future Development Trends of 21700 Battery Safety Vents

(1) Intelligent and Sensor-Integrated Vents

Future vents may combine pressure and temperature sensors for early warning and controlled release, improving intelligent safety management.

(2) Material Optimization

High-strength, corrosion-resistant, and heat-resistant alloys or composites will improve long-term stability under extreme environments.

(3) Miniaturization

With increasing energy density, vents need to be optimized for size to maintain efficient venting without compromising battery volume or energy density.

(4) Lifecycle Safety Management

Vent design will integrate battery lifespan, cycle count, and thermal management to ensure safety from manufacturing to usage and end-of-life.

Peroration

The safety vent is a core component of the 21700 battery safety system. By effectively releasing pressure during overpressure or extreme conditions, it protects batteries, modules, and end devices. With the broader adoption of high-energy-density batteries, optimizing vent design and performance is increasingly important. Future integration with intelligent monitoring, advanced materials, and miniaturized designs will enhance the vent's role, providing reliable safety for electric vehicles, energy storage, and portable devices. Thank You.

Related Articles

What are the Different Types of 21700 Battery Positive Caps?

What is 21700 Tabless Design?