BASF Shanshan Battery Materials Co., Ltd. Vice GM Mr. Marc Poetzsch Visits JOINSUN Lithium Cell Factory

巴斯夫杉杉电池材料有限公司总经理马克波茨奇先生参观吉欣锂电芯工厂

El vicepresidente Sr. Marc Poetzsch de BASF Shanshan Battery Materials Co., Ltd. visita la fábrica de celdas de litio de Joinsun

Le vice-directeur M. Marc Poetzsch de BASF Shanshan Battery Materials Co., Ltd. visite l’usine de cellules lithium de Joinsun

Заместитель генерального директора г-н Марк Поэтш из BASF Shanshan Battery Materials Co., Ltd. посещает завод литиевых элементов Joinsun

Wiceprezes Pan Marc Poetzsch z BASF Shanshan Battery Materials Co., Ltd. odwiedza fabrykę ogniw litowych Joinsun

On August 5, 2024

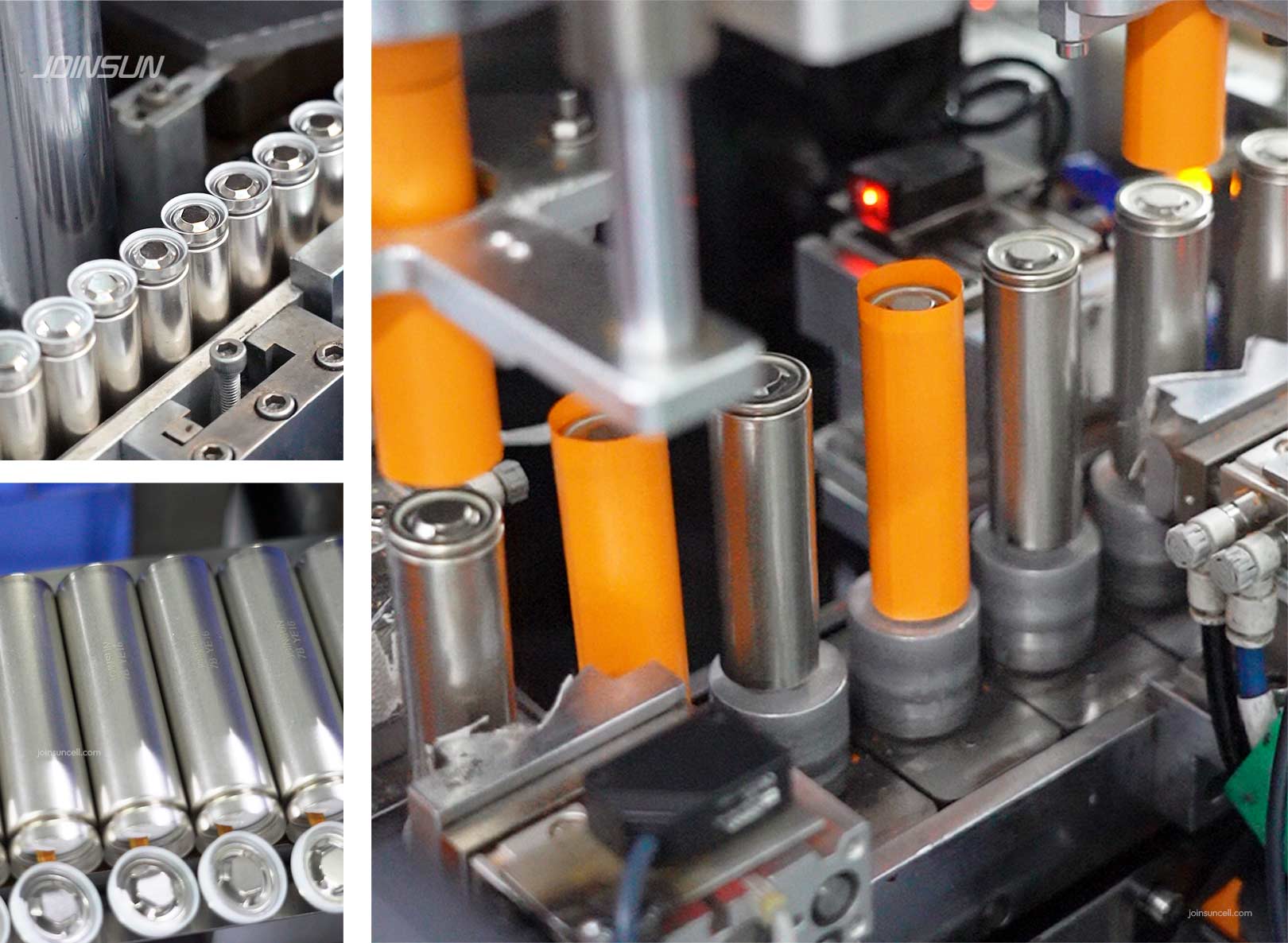

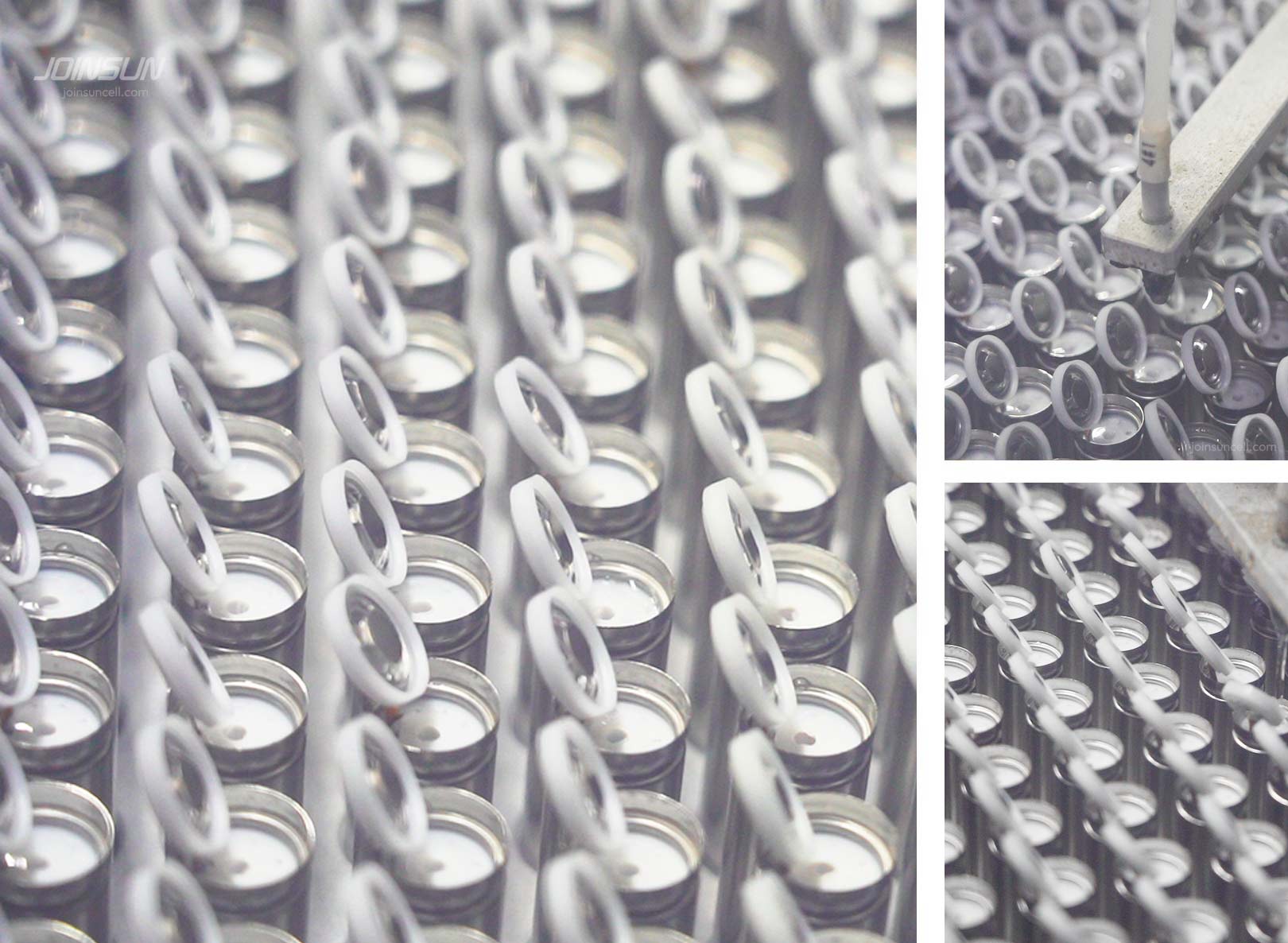

The Mr. Poetzsch his delegation visited the JOINSUN lithium cell factory for an in-depth exchange. The purpose of the visit was to gain a comprehensive understanding of JOINSUN's production capabilities, quality control system, and future technological development in the field of lithium cell manufacturing. Both parties engaged in in-depth discussions on topics such as battery material cooperation, industry chain integration, and trends in the new energy sector.

波茨奇先生莅临吉欣锂电芯工厂参观交流,深入了解吉欣在锂电芯制造领域的生产能力、质量控制体系以及未来的技术发展方向。双方围绕电池材料合作、产业链协同以及新能源领域的发展趋势等议题展开了深入探讨。

El Sr. Poetzsch y su delegación visitaron la fábrica de celdas de litio de Joinsun para un intercambio en profundidad. El propósito de la visita fue obtener una comprensión completa de las capacidades de producción de Joinsun, su sistema de control de calidad y el desarrollo tecnológico futuro en el campo de la fabricación de celdas de litio. Ambas partes participaron en discusiones detalladas sobre temas como la cooperación en materiales para baterías, la integración de la cadena de la industria y las tendencias en el sector de la nueva energía.

M. Poetzsch et sa délégation ont visité l’usine de cellules lithium de Joinsun pour un échange approfondi. L’objectif de la visite était de comprendre de manière complète les capacités de production de Joinsun, son système de contrôle de qualité et le développement technologique futur dans le domaine de la fabrication de cellules lithium. Les deux parties ont participé à des discussions approfondies sur des sujets tels que la coopération en matière de matériaux pour batteries, l’intégration de la chaîne industrielle et les tendances dans le secteur des nouvelles énergies.

Г-н Поэтш и его делегация посетили завод литиевых элементов Joinsun для углубленного обмена опытом. Цель визита заключалась в том, чтобы получить полное представление о производственных возможностях Joinsun, системе контроля качества и будущем технологическом развитии в области производства литиевых элементов. Обе стороны провели углубленные обсуждения по таким темам, как сотрудничество в области материалов для батарей, интеграция отраслевой цепочки и тенденции в секторе новой энергии.

Pan Poetzsch wraz ze swoją delegacją odwiedził fabrykę ogniw litowych Joinsun w celu dogłębnej wymiany doświadczeń. Celem wizyty było uzyskanie pełnego zrozumienia możliwości produkcyjnych Joinsun, systemu kontroli jakości oraz przyszłego rozwoju technologicznego w dziedzinie produkcji ogniw litowych. Obie strony uczestniczyły w szczegółowych dyskusjach na tematy takie jak współpraca w zakresie materiałów do baterii, integracja łańcucha przemysłowego oraz trendy w sektorze nowej energii.

The JOINSUN management team warmly received the guests and guided them through the cell production lines, laboratories, and automated production lines. The BASF shanshan delegation highly praised JOINSUN's technical strength and manufacturing expertise and expressed their expectations for further cooperation in lithium battery materials and sustainable energy in the future.

吉欣管理层团队非常热情的接待了来访嘉宾,并一起参观了电芯生产线、实验室及自动化生产线。巴斯夫杉杉代表团对吉欣的技术实力与制造能力给予了高度评价,并表示期待未来在锂电池材料及可持续能源领域展开更深入的合作。

El equipo de gestión de Joinsun recibió cordialmente a los invitados y los guió a través de las líneas de producción de celdas, laboratorios y líneas de producción automatizadas. La delegación de BASF Shanshan elogió altamente la fortaleza técnica y la experiencia en fabricación de Joinsun y expresó sus expectativas de una mayor cooperación en materiales para baterías de litio y energía sostenible en el futuro.

L’équipe de direction de Joinsun a chaleureusement accueilli les invités et les a guidés à travers les lignes de production de cellules, les laboratoires et les lignes de production automatisées. La délégation de BASF Shanshan a vivement loué la compétence technique et l’expertise en fabrication de Joinsun et a exprimé ses attentes pour une coopération future dans les matériaux pour batteries lithium et l’énergie durable.

Руководство Joinsun тепло приняло гостей и провело их по производственным линиям элементов, лабораториям и автоматизированным производственным линиям. Делегация BASF Shanshan высоко оценила технический потенциал и производственный опыт Joinsun и выразила свои ожидания дальнейшего сотрудничества в области материалов для литиевых батарей и устойчивой энергетики в будущем.

Zespół zarządzający Joinsun serdecznie przyjął gości i oprowadził ich po liniach produkcyjnych ogniw, laboratoriach oraz zautomatyzowanych liniach produkcyjnych. Delegacja BASF Shanshan wysoko oceniła siłę techniczną i doświadczenie produkcyjne Joinsun oraz wyraziła oczekiwania dalszej współpracy w zakresie materiałów do baterii litowych i zrównoważonej energii w przyszłości.