What is the NCM811 and its Advantages?

Blog | Published by Alex on July 8, 2025

What Is NCM811? The 8:1:1 Cathode Chemistry

The "811" designation refers to the cathode material composition—Nickel (Ni), Cobalt (Co), and Manganese (Mn) in an 8:1:1 ratio. This high-nickel content significantly enhances energy density, as nickel contributes the most to specific capacity. Public data shows that NCM811 cathode material can deliver up to 190mAh/g, compared to 166mAh/g for mainstream NCM523. Accordingly, the highest energy density of NCM523 reaches ~200Wh/kg, NCM622 around 230Wh/kg, and NCM811 can exceed 280Wh/kg. This substantial increase in energy storage makes NCM811 highly attractive for electric vehicles (EVs), where range anxiety remains a consumer concern. EVs equipped with NCM811 packs can easily surpass 600 km in range, with some exceeding 800 km, significantly boosting market appeal.

Dependence Reduction On Cobalt and Cost Advantage

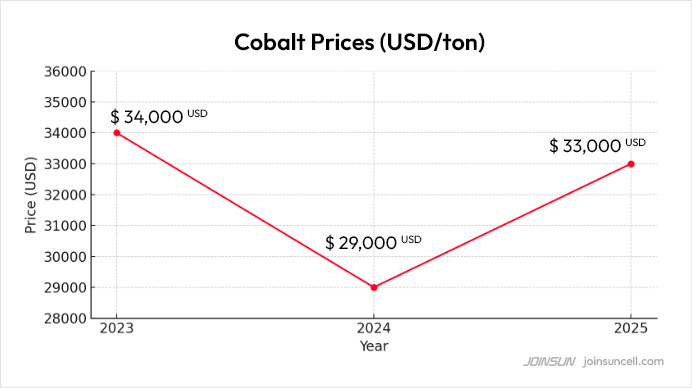

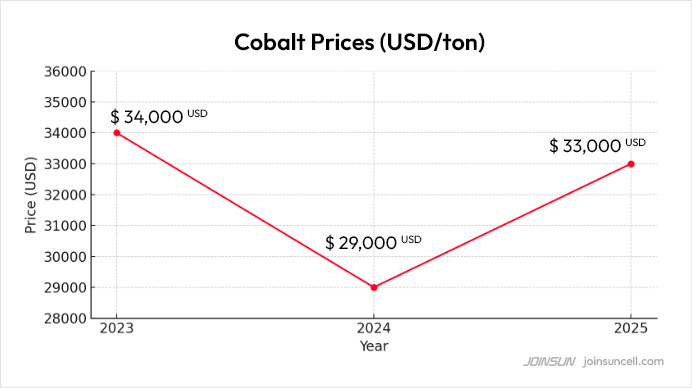

Cost factors also drive the shift toward NCM811. Cobalt' s volatility and high pricing—due to its limited supply concentrated in regions like the DRC—has led manufacturers to seek alternatives. In 2023,

Cobalt prices USD $34,000/ton, 2024, USD $29,000/ton, 2025, USD $33,000/ton, while NCM811 contains only about 20% of the cobalt found in NCM523. For an EV with a 70kWh battery, switching to NCM811 can save thousands of yuan in cobalt costs, enhancing competitiveness.

NCM811 vs. NCM111

Compared to NCM111, NCM811 offers significant advantages in energy density and discharge performance:

| Items |

NCM111 |

NCM811 |

| Ni:Co:Mn Ratio |

1:1:1 |

8:1:1 |

| Specific Capacity (mAh/g) |

150–160 |

180–200 |

| Energy Density (Wh/kg) |

~180–200 |

~260–280 |

| Discharge Rate Performance |

Stable, moderate |

Superior high-rate performance |

| Cost |

High (Higher cobalt) |

More Cost-Effective (Lower cobalt) |

Thanks to its high nickel content, NCM811 significantly improves specific capacity and energy density. It delivers stronger discharge performance, making it ideal for electric vehicles, scooters, e-bikes, power tools, and energy storage systems.

* NCM111 is a ternary material with a Ni:Co:Mn (Nickel:Cobalt:Manganese) ratio of 1:1:1

* NCM811 is a

high-nickel ternary material with a Ni:Co:Mn (Nickel:Cobalt:Manganese) ratio of 8:1:1

NCM811 vs. NCM523

NCM811 and NCM523 are two common lithium-ion battery cathode chemistries, differing in their nickel, cobalt, and manganese content. NCM811 offers higher energy density and lower cobalt dependency.

| Property |

NCM523 |

NCM811 |

| Ni:Co:Mn Ratio |

5:2:3 |

8:1:1 |

| Specific Capacity (mAh/g) |

~160–170 |

~180–200 |

| Energy Density (Wh/kg) |

~200 |

~260–280 |

| Weight |

Heavier |

Lighter |

| Extended Driving Range |

Medium |

Longer |

| Cobalt Content |

Moderate |

Low |

| Cost |

Medium |

Lower (Less cobalt) |

* NCM523 is a ternary material with a Ni:Co:Mn (Nickel:Cobalt:Manganese) ratio of 5:2:3

1. NCM 811 vs NCM 523 Starting

With the rapid expansion of the new energy vehicle and energy‑storage markets, ternary lithium batteries have become mainstream due to their high energy density, long cycle life, and good controllability. As the core technology of ternary lithium, NCM (nickel–manganese–cobalt oxide) batteries derive their performance and cost directly from the cathode’s chemical ratio. Two widely used types on the market are NCM 811 (Ni:Co:Mn = 8:1:1) and NCM 523 (Ni:Co:Mn = 5:2:3). This article provides an in‑depth analysis from multiple angles, including chemical composition, performance differences, manufacturing processes, supply‑chain costs, and market trends.

2. NCM 811 and NCM 523 Chemical Composition and Material Characteristics

(1) NCM 523

Nickel content 50%, cobalt 20%, manganese 30%.

Features: moderate energy density, relatively higher material cost.

(2) NCM 811

Nickel content 80%, cobalt 10%, manganese 10%.

Features: high energy density, lightweight, clear cost advantage (low cobalt)

3. NCM 811 vs NCM 523 Performance Comparison

(1) Energy density and range

The high‑nickel design of NCM 811 stores more energy per unit mass, significantly improving EV range. For battery packs of the same weight, 811 can increase energy capacity by roughly 25–35% over 523.

(2) Cycle life

Structural instability associated with high nickel accelerates capacity fade. NCM 523 typically offers higher cycle counts, making it suitable for storage systems and low‑speed EVs where long life is crucial.

4. NCM 811 vs NCM 523 Supply Chain and Cost Analysis

(1) Raw‑material cost

NCM 811: lower cobalt; nickel dominates cost, and nickel prices are relatively more stable.

NCM 523: higher cobalt content; cost strongly affected by cobalt price volatility.

(2) Manufacturing cost

NCM 811: higher demands on equipment precision and yield; larger upfront investment.

NCM 523: mature processes with high yields; slightly higher unit cell cost but well‑controlled.

(3) Supply‑chain risk

NCM 811: NCM 811 reduces cobalt proportion and thus lowers supply‑chain risk.

NCM 523: Cobalt resources are concentrated (e.g., the DRC), making NCM 523 more exposed to geopolitical risks.

NCM 811 vs NCM 523: Which is Better Suited for Which Applications?

NCM 811: High energy density, long range, and lighter weight, suitable for e-bikes, electric scooters, balance scooters, e-rickshaws, drones, etc.

NCM 523: Power tools, garden tools, etc.

* Here is Joinsun NCM 811 21700 Battery Products Catalogue:

Joinsun 3.6V 21700 Series

* Here is Joinsun NCM 523 18650 Battery Product:

Joinsun INR 18650-20D 3.6V 2Ah (2000mAh)

Manufacturing Demands and Process Sensitivity

Manufacturing NCM811 also demands strict process control, high-precision equipment, and ultra-clean production environments. The sintering process requires tightly regulated temperatures, necessitating advanced kilns and temperature control systems. The material is also highly moisture-sensitive—production humidity must stay below 1%, increasing operational costs. Moreover, NCM811 requires advanced high-voltage electrolytes and separators with higher thermal/mechanical tolerance, raising technical thresholds across the supply chain.

Innovations to Improve Performance and Safety

Despite these hurdles, the performance and safety of 21700 NCM811 cells are improving with advances in materials science and thermal management. Researchers are exploring doping (e.g., Al, Mg), surface coatings, and next-gen cooling technologies such as liquid cooling to overcome key issues. For example, some automakers now implement comprehensive liquid thermal management in EVs using NCM811 cells, ensuring stable operation across various conditions.

Expanding Application Scenarios

Application scenarios are also expanding beyond EVs. In the fast-growing energy storage sector, NCM811’s high energy density improves space utilization and system efficiency. In portable electronics, drones, and laptops, it delivers longer runtimes and better user experience.

Ecosystem Growth and Industry Collaboration

Industry-wide, investments in the 21700 NCM811 ecosystem are increasing, fostering a complete supply chain from materials R&D to cell manufacturing and pack assembly. Collaborative development between battery manufacturers and automakers, or material suppliers and cell producers, accelerates commercialization and innovation.

Outlook: Driving the Future of Energy Storage

Looking ahead, with ongoing breakthroughs, 21700 NCM811 cells are poised to offer better performance, lower costs, and improved safety—supporting applications from EVs and ESS to consumer electronics. However, sustainability concerns—particularly regarding recycling and end-of-life battery management—must also be addressed. With industry collaboration and technological progress, 21700 NCM811 cells are expected to become a key pillar of the clean energy transition, contributing significantly to sustainable mobility and energy systems worldwide.

Joinsun NCM 811 21700 lithium-ion cell series offers high energy density, long lifespan, excellent safety, advanced manufacturing, reduced cobalt reliance, and cost efficiency. Widely used in power banks, portable power stations, scooters, e-bikes, 24 hours security products, flashlight, solar battery, power tools, electric garden tools, 3C digital prodcuts, and more.

Related Articles

High-Nickel Technology for High-Energy-Density 21700 Battery